NHsolution

Integrated 160 MW Electrolysis and Methanol Synthesis Plant with Carbon Capture and Oxyfuel Combustion

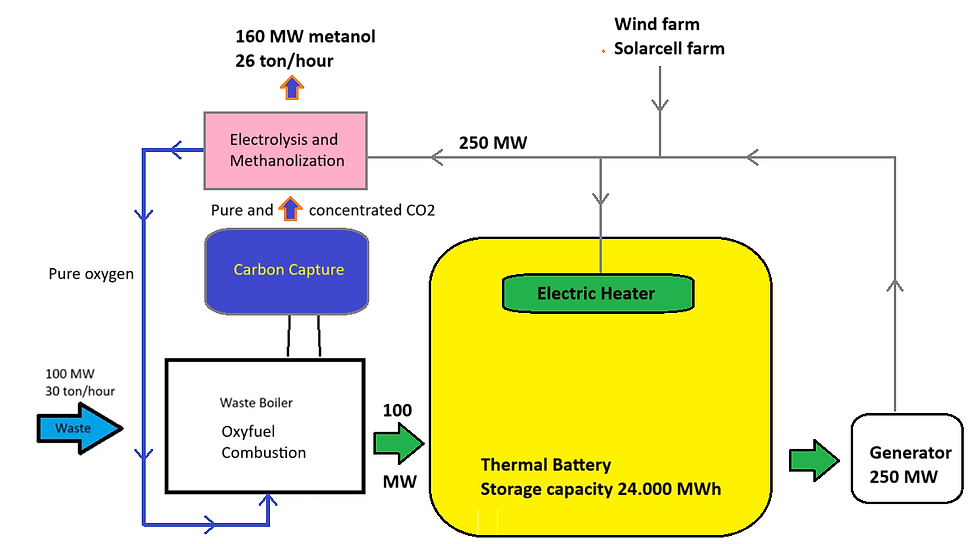

A 160 MW electrolysis and methanol synthesis facility is integrated with a waste-to-energy plant equipped with carbon capture (CC). The pure oxygen generated as a byproduct of electrolysis is fed directly into the waste boiler, enabling oxyfuel combustion — i.e., combustion using pure oxygen instead of air, thereby eliminating nitrogen from the process.

As a result, the flue gas from the boiler contains nearly 100% CO₂ (compared to just ~20% in conventional combustion), which can be cleaned using a bag filter and used directly in the methanol synthesis unit. Here, the CO₂ is bound with hydrogen from electrolysis to produce methanol.

Thermal Battery and Power Grid Integration

On the power generation side, the waste boiler heats a thermal battery, which also stores surplus electricity from wind turbines and solar panels. When renewable sources are unavailable (i.e., during low wind or no sun), the thermal battery supplies energy to the steam generator and turbine, effectively stabilizing the system.

Since wind and solar provide electricity about 60–70% of the time, this configuration allows the integrated system to operate with a year-round efficiency (capacity factor) exceeding 90%.

Economic Overview

-

A 100 MW waste boiler combined with a thermal battery, steam generator, and turbine has an estimated investment of DKK 4 billion

-

The 160 MW electrolyzer and methanol synthesis unit adds another DKK 2 billion

-

Including operation, maintenance, and capital cost, and assuming a electricty price of DKK 0.25/kWh, the facility can produce methanol at a cost of ~DKK 400 per MWh — roughly equivalent to the cost of gasoline or diesel

Scaling Scenario

If a 250 MW methanol facility is integrated into a 1 GW multi-fuel power plant — with waste combustion feeding into a shared thermal battery — the overall system economics improve significantly, leading to even lower methanol production costs.

A good example of such an integrated plant is Avedøre 2, located near Copenhagen.

Let me know if you want this version adapted for a specific format (e.g. slide deck, executive summary, technical white paper) or expanded with graphics or calculations.

Electrolysis with methanol production combined with a power plant equipped with a thermal battery.

There are some straightforward and unique synergies between waste incineration, oxyfuel combustion, and thermal energy storage.

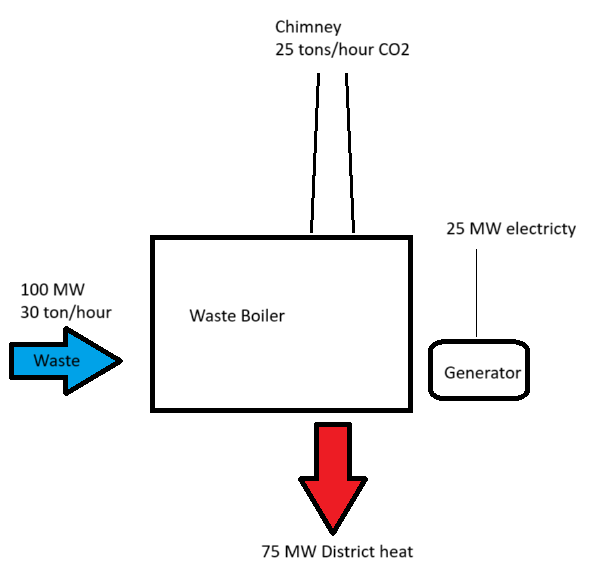

The principle behind a typical Danish waste-to-energy plant is as follows:

The power plant operates continuously, and large portions of its electricity production conflict with generation from renewable energy sources.

Carbon Capture (CC) at a waste-to-energy plant costs approximately DKK 1,000 per ton of CO₂, which alone results in a CO₂ cost of DKK 200 per MWh of methanol produced. In comparison, the current market price of natural gas is around DKK 300 per MWh. The high cost is mainly due to the complex and advanced installations required for retrofitting carbon capture systems on a waste incineration plant.

This setup — combining oxyfuel combustion, a waste-to-energy plant, and a thermal battery — offers a promising alternative. See the diagram below:

The art of integration

renewable energy (RE)

Electrofuels such as methane and methanol are crucial tools in achieving a fossil-free society.

These energy carriers can be used in aviation, transportation, and in the chemical industry — particularly in plastic production.

To produce energy carriers like methane and methanol that can be used directly within the existing infrastructure (natural gas grid, fuel stations, tanker trucks), large volumes of CO₂ are required at affordable prices.